HPPV-PS Series

Proportional Pinch Valves With Position Sensing

Applications

- Biopharmaceutical Manufacturing

- Biochemical/Bioprocess Engineering

- Bioreactors

- Dosage Systems

- Lab Analysis

Advantages

- 12x pinch force (50lbs.) of solenoid valve

- Tube O.D. size range:0.250”-0.500”

- Real-Time position feedback

- Non-Contact fluid metering

- Position memory after power loss

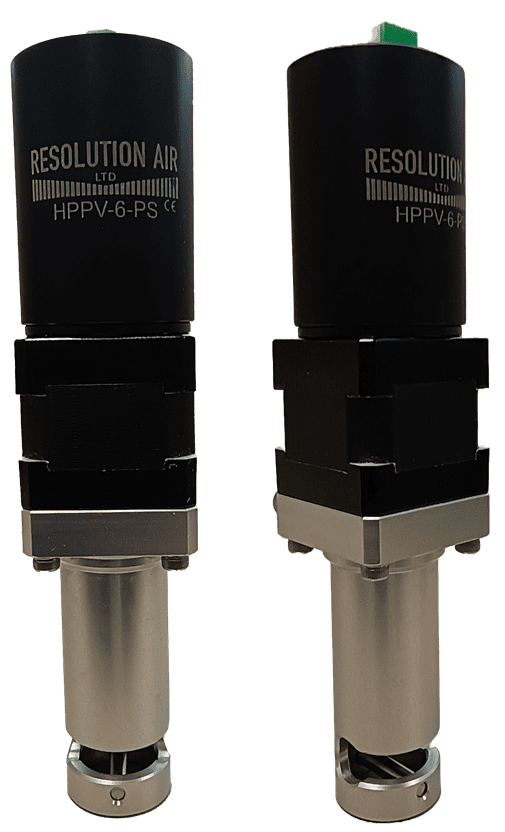

Resolution Air, Ltd. expands its innovative portfolio of patented Proportional Pinch Valves with their HPPV-PS Position Sensor Series. This advanced feature integrates a compact position sensor offering precise linear position feedback for critical fluid handling applications. Replacing traditional home sensors and encoder combinations, this technology provides a streamlined solution with numerous benefits for industries requiring precision, reliability, and continuous position feedback. As well as providing fluid metering, the HPPV-PS series generates 12x (50 lbs.) the pinch force of a typical solenoid pinch valve.

Proportional Pinch Valves with Position Sensing

Resolution Air, Ltd. expands its innovative portfolio of patented Proportional Pinch Valves with their HPPV-PS Position Sensor Series. This advanced feature integrates a compact position sensor, offering precise linear position feedback for critical fluid handling applications. The new technology replaces traditional home sensors and encoder combinations, providing a streamlined solution with numerous benefits for industries requiring precision, reliability, and continuous position feedback.

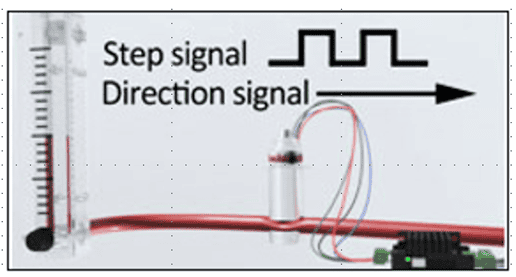

Control Requirements

The bi-polar stepper motors used in the Resolution Air, Ltd. Proportional Pinch Valves require two input control signals, a step signal and a direction signal.

Step Signal- A pulse width modulated (PWM) signal. Each pulse generates a single step. For the MPPV-Series, a single step equates to 7.5 degrees of motor rotation (1.8 degrees for the HPPV-Series). Since the motor shaft is coupled to an integral leadscrew, this rotation translates into 0.0005”/step of linear motion.

Direction Signal- A digital binary signal which determines the clockwise/anti clockwise motor rotation.

There are two primary methods for generating, sequencing, and amplifying the step and direction signals required for stepper motor control.

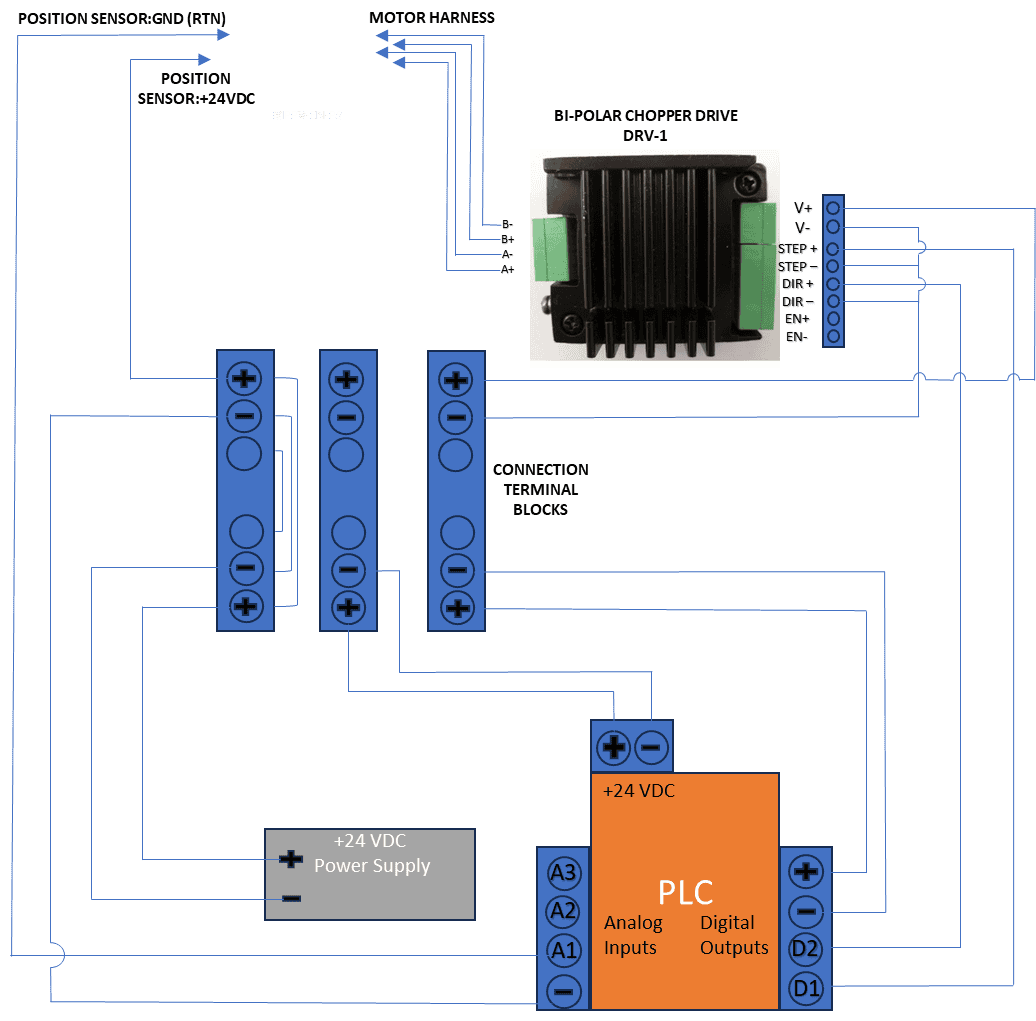

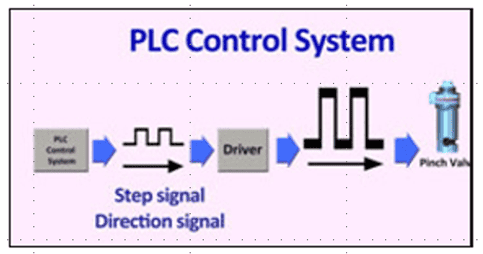

PLC Based Control System

Signals generated by a Programmable Logic Controller (PLC) are amplified and sequenced by a Bi-Polar Chopper Driver (DRV-1) to the level required to drive the Proportional Pinch Valve.

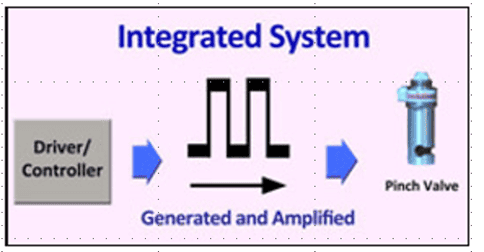

Bi-Polar Driver/Controller System

The Step and Direction signals are generated, sequenced, and amplified by a single control device known as a Bi-Polar Driver/Controller.

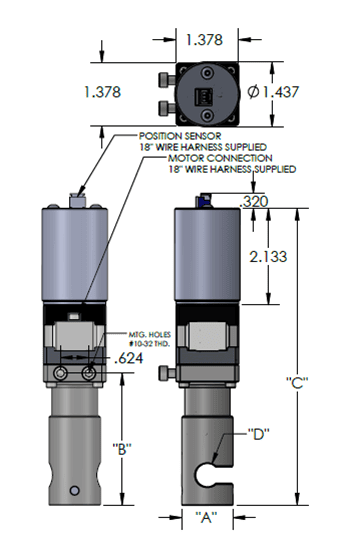

VALVE DIMENSIONS

| HPPV-8-PS | |

|---|---|

| Dim. A (in.) | 1.125 |

| Dim. B (in.) | 2.902 |

| Dim. C (in.) | 6.535 |

| Dim. D (in.) | 0.500 |

| HPPV-6-PS | |

|---|---|

| Dim. A (in.) | 0.937 |

| Dim. B (in.) | 2.549 |

| Dim. C (in.) | 6.182 |

| Dim. D (in.) | 0.375 |

| HPPV-4-PS | |

|---|---|

| Dim. A (in.) | 0.937 |

| Dim. B (in.) | 2.400 |

| Dim. C (in.) | 6.032 |

| Dim. D (in.) | 0.250 |

| POSITION SENSOR PERFORMANCE CHARACTERISTICS | |

|---|---|

| Supply Voltage | 8-24 VDC |

| Output Smoothness | 0.1% max. at 10″ to 18″ per minute |

| Backlash | 0.003″ maximum |

| Sensor Output | 4-20 mA (2 wire) |

| Sensor Resolution | Essentially infinite |

| Valve Position Resolution | 0.0005″/Full Step |

| Electrical Connection | 18″ Wire harness included |

| POSITION SENSOR SETTINGS | |

| Piston Position | mA Value |

| Full Open-Hard Stop | 4.00 mA. |

| Full Open-Top of Tube | |

| Full Travel-0.500″ | 20 mA |

| ELECTRICAL SPECS.: STEPPER MOTOR | |

| Wiring | BiPolar |

| Step Angle | 7.5 Degree |

| Motor Voltage | 5 VDC |

| Supply Voltage | 24 VDC – 40 VDC |

| Current/Phase | 385 A Max |

| Resistance/Phase | 13 Ω |

| Inductance/Phase | 10.6 mH |

| Power Consumption | 3.85 Watts |

| Rotor Inertia | 1.07 gcm^2 |

| Temperature Rise | 135° F |

| Insulation Resistance | 20 MΩ |

Download the HPPV-EN-PS-Series Technical Data Sheet

Wiring Schematic Example

HPPV-PS + PLC + P.SUPPLY + BI-POLAR CHOPPER DRIVE