Proportioning valves that combine the fluid metering characteristics of the needle valve with the fluid separation of the pinch valve

Precision Flow Control Pinch Valve

Providing Sanitary Fluid Separation & Flow Metering

Preserving the integrity of a fluid passing through a non-contact system is essential in a variety of sanitary applications. Ever-increasing levels of sophistication in new technologies have led to more stringent performance demands, and processes need to be regulated with greater speed and accuracy. Needle valves have excellent fluid metering characteristics but poor fluid separation characteristics. Conversely, pinch valves have superior fluid separation characteristics but inadequate fluid metering ability. In order to meet application requirements, these two types of valves would typically be used in tandem.

Recognizing the need for a better approach, Resolution Air’s valve design allows the benefits of pinch valve fluid separation to be combined with proportional valve control for sanitary processes that require highly accurate incremental flow regulation where cleanliness and sterility is required. Previously, this could only be accomplished with a manually operated control valve. The newly developed Miniature Proportional Pinch Valve series has been engineered to meet the needs of the most challenging precision flow applications in industries such as bio-chemical, food and beverage, and healthcare.

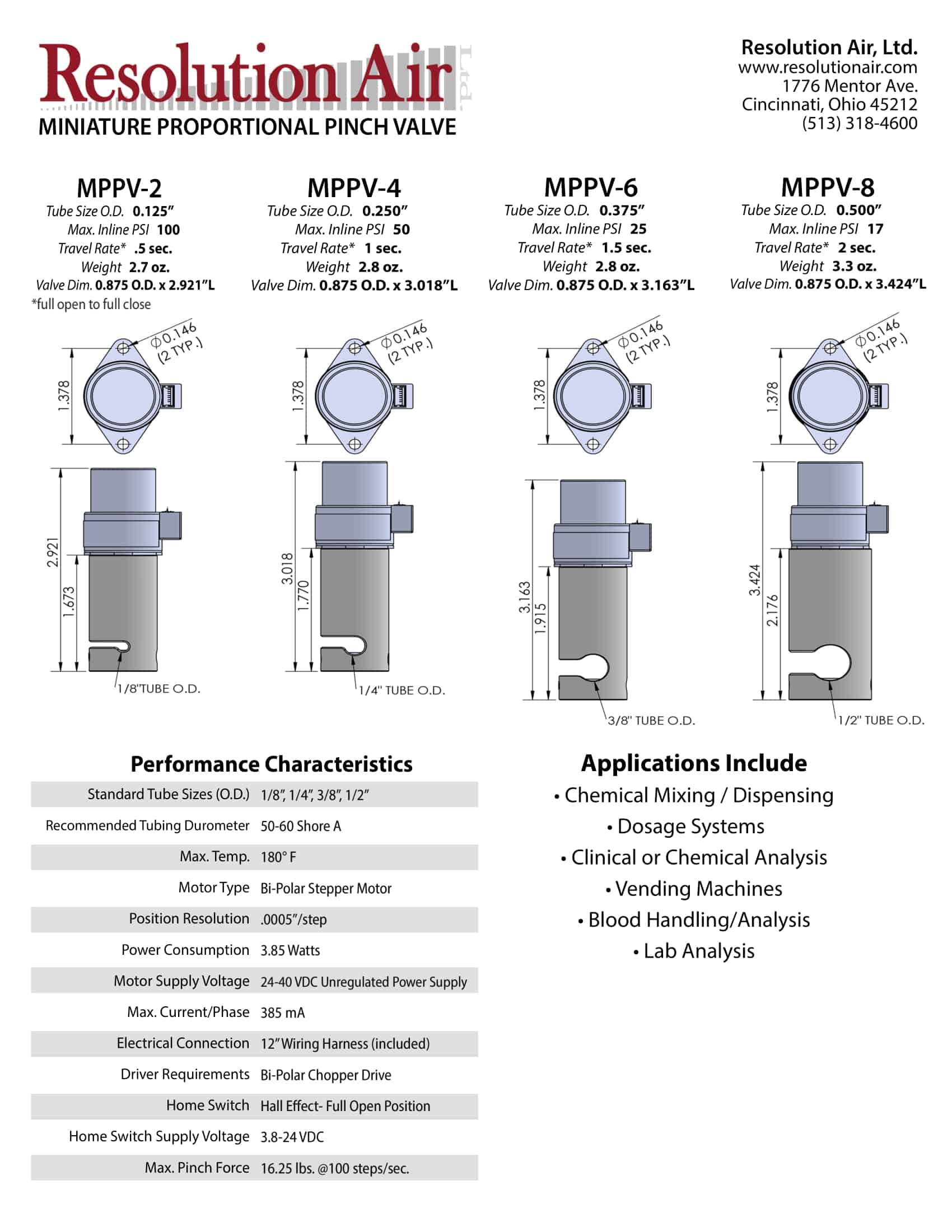

Miniature Proportional Pinch Valve Design

The MPPV series allows physical separation between the valve from corrosive or high purity process fluids, while providing the incremental flow control offered in a conventional proportional valve. The MPPV pinches a fluid filled, pressurized, low durometer tube to regulate the flow of the liquid or gas through the tube. The design incorporates a stepper linear actuator and custom piston, which provide precision proportional control functioning in the valve. In addition, with the actuator’s non-back driveable lead screw, power is only required when changing position.

Available in a variety of size configurations to meet a wide range of needs, Resolution Air Miniature Proportional Pinch Valves are ideally suited for use in portable and handheld equipment designed for analytical and diagnostic processes.

Advantage of the M-Series Over Other Valves

Miniature proportional pinch valves offer several advantages over other types of valves, such as check valves, butterfly valves, needle valves, and actuator valves. These benefits include:

- Automated control

- No physical contact with process fluid

- High resolution flow control

- Maintains position with power loss

- Home switch provides digital output for full open position

- Durable construction

- Tested performance

- High repeatability

- Low power consumption

- No leakage

- Long performance life

- Light weight, low profile design

- Superior corrosion resistance

- Valve body material option: Stainless Steel

M-Series Pinch Valve Applications Include

- Chemical Mixing/Dispensing

- Dosage Systems

- Clinical or Chemical Analysis

- Vending Machines

- Blood Handling/Analysis

- Lab Analysis