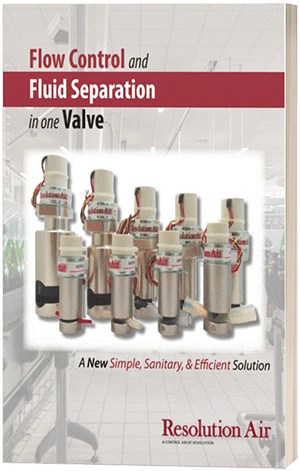

Introduction to Proportional Pinch Valves

The patent pending M-series and P-series proportional pinch valve designs physically separate the valve from corrosive or high purity process fluids, while providing the precise flow control offered in a conventional proportional valve. Our valves pinch a fluid filled, pressurized, low durometer tube regulating the flow of the liquid or gas flowing through the tube. The designs incorporate a stepper linear actuator and custom piston, which provide precision proportional valve control. In addition, due to the actuator’s non-back-driveable lead screw, power is only required to change position.

MPPV and PPV Advantages

A primary benefit of proportional pinch valves is automating the metering process of liquids and gases in open and closed loop control systems. In addition, Resolution Air, Ltd valves are also being utilized in applications requiring simple ON/OFF control because they generate significantly higher pinch forces(4x-8x) compared to a traditional solenoid pinch valve. As a result, our valves are quickly replacing traditional low force solenoid pinch valves in many markets including medical device and life sciences, where precise sanitary fluid metering is critical to the application

Features

- Automated control

- No physical contact with process fluid

- High resolution flow control

- Maintains position with power loss

- Home switch provides digital output for full open position

- Durable construction

- Tested performance

- High repeatability

- Low power consumption

- No leakage

- Long performance life

- Light weight, low profile design

- Superior corrosion resistance

- Valve body material option: Stainless Steel

Applications Include

- Chemical Mixing/Dispensing

- Dosage Systems

- Clinical or Chemical Analysis

- Vending Machines

- Blood Handling/Analysis

- Lab Analysis